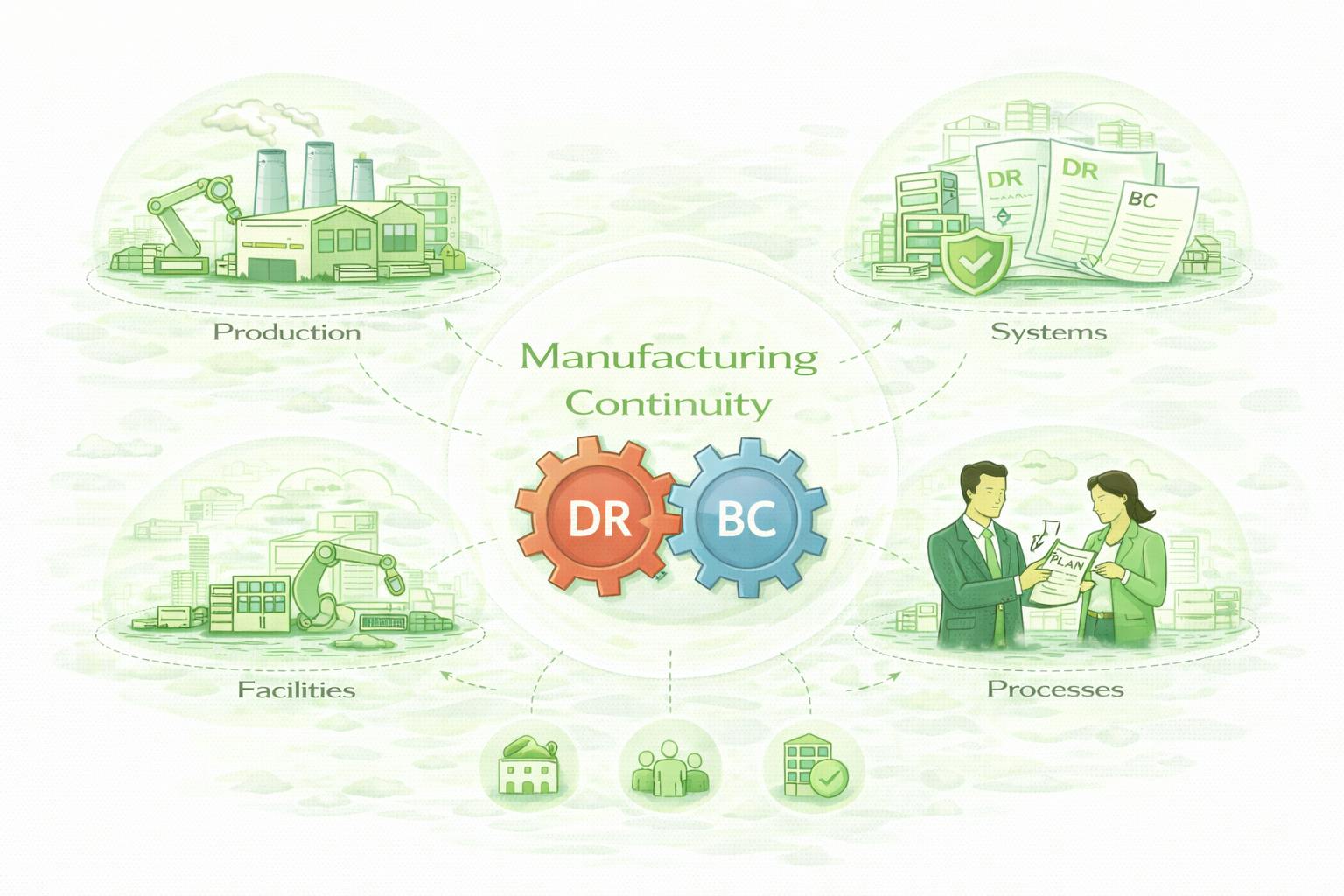

Most disaster recovery and business continuity plans look good on paper.

They fail when production is on the line.

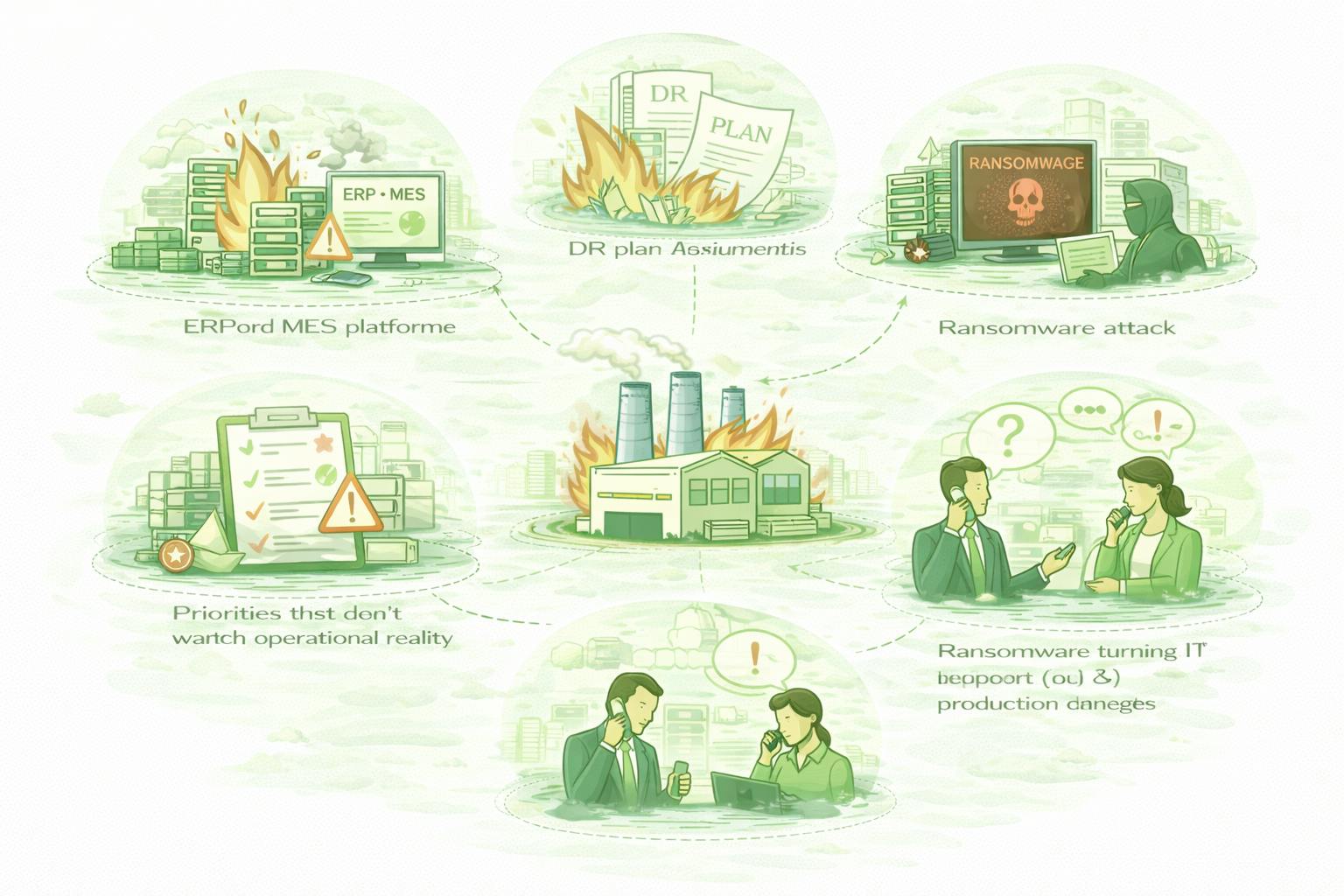

Common issues we see:

- DR plans that focus on servers but ignore production systems

- ERP and MES platforms becoming single points of failure

- Recovery priorities that don’t match operational reality

- Business continuity plans that haven’t been tested in years

- Ransomware turning IT incidents into full production outages

- Nobody's clear on who makes the call during an incident

For a lot of California manufacturers, these problems get worse when you add in earthquakes, wildfires, tight regulations, and plants spread across multiple sites.

When systems crash, you don't need a debrief. You need someone to make a decision and move fast.