Top cloud solutions for manufacturing companies in California

California manufacturers are under pressure from every direction. Labor is expensive. Energy costs are unpredictable. Supply chains still feel fragile. And ransomware has moved from an IT problem to an operational threat.

Cloud solutions are often pitched as the fix. But for manufacturing companies, especially small and mid-sized ones, the wrong cloud decision can create more risk, not less.

This guide is written for California manufacturing leaders who need cloud solutions that support production, protect the business, and scale without disrupting operations. No hype. Just what works.

Why California Manufacturers Are Rethinking Cloud Solutions

Manufacturing in California is different. What works in other states doesn’t always translate here.

Unique challenges in California manufacturing

The manufacturers in California struggle with more expensive labor, less profit margin, and more rigorous regulations. A large number of them are working in aerospace, food and beverage, medical devices, or specialized industrial sectors where downtimes are absolutely avoided.

On top of that, if you add the risk of natural disasters to their list of worries, it makes things even more difficult. The occurrences of earthquakes, wildfires, and power outages bring contingency planning for business operations to an absolute necessity.

The risk of staying on-prem too long

Many manufacturers still rely on aging on-prem servers because “they’ve always worked.” But those systems often lack:

- Reliable disaster recovery

- Strong ransomware protection

- Predictable scaling as the business grows

When something breaks, recovery is slow. And slow recovery on a manufacturing floor gets expensive fast.

Cloud solutions are no longer about modernization. They are about survival and control.

The Main Types of Manufacturing Cloud Solutions

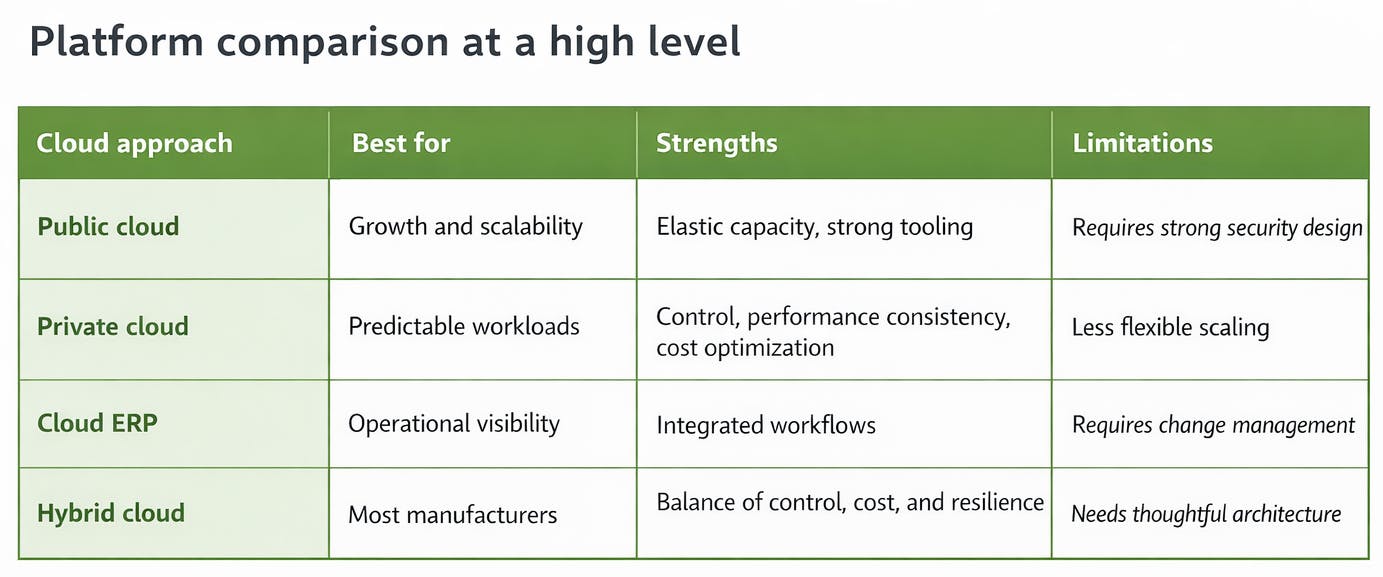

Not all cloud solutions are the same. And manufacturing companies rarely fit into a single bucket.

Cloud infrastructure for manufacturing systems

This includes servers, storage, backups, and disaster recovery hosted in the cloud. It’s often the first step for manufacturers with legacy applications that cannot be replaced overnight.

This approach improves resilience without forcing major application changes.

Cloud ERP and manufacturing platforms

Cloud-based ERP and manufacturing systems handle production planning, inventory, finance, and reporting. For growing manufacturers, these platforms can reduce manual work and improve visibility across operations.

But they require careful planning. A rushed ERP move can disrupt production instead of improving it.

Hybrid cloud for manufacturing plants

This is where most California manufacturers land.

Critical systems stay close to the production floor. Cloud platforms handle backups, analytics, remote access, and disaster recovery.

Hybrid cloud accepts reality. Manufacturing floors need local control. The business still needs cloud resilience.

Top Cloud Platforms Used by Manufacturing Companies

The platform's relevance is lower than its design and management, yet a few basic elements still determine the majority of the factory cloud environments.

On one hand, public cloud services such as as Amazon Web Services, Microsoft Azure, and Google Cloud offer the advantages of scalability and dependability. On the other hand, the private cloud makes it possible to gain better control and stability.

Private cloud environments offer more control and predictability. Manufacturing-focused cloud ERP platforms add industry-specific functionality.

What matters more than the name on the platform is how it supports production.

What manufacturers should actually evaluate

Instead of asking which cloud is “best,” ask:

- How reliable is this during peak production?

- How fast can systems be recovered after an outage?

- How well does it integrate with shop floor systems?

- Who is accountable when something fails?

- What do the costs look like as needs scale?

Security, Compliance, and Ransomware Risk in Manufacturing

Manufacturers are prime ransomware targets because attackers know downtime creates leverage.

Why manufacturing environments are vulnerable

Many plants have flat networks where IT and operational technology overlap. Legacy systems are hard to patch. Backups are often untested.

One incident can halt production, delay shipments, and damage customer trust.

What secure manufacturing cloud solutions must include

A secure cloud environment for manufacturing should provide:

- Immutable backups that cannot be altered by attackers

- Network segmentation between IT and production systems

- Tested disaster recovery plans with clear recovery times

- Compliance readiness for audits and customer requirements

Security is not a bolt-on feature. It is part of the architecture.

How California Manufacturers Should Choose a Cloud Solution

This is where many cloud projects go wrong. Decisions are made based on features instead of risk.

Executive questions that matter

Before choosing a provider or platform, leadership should be able to answer:

- What happens if this system goes down during production

- How long does recovery realistically take

- Who owns security and compliance responsibilities

- Can this scale without re-architecting everything

If these answers are unclear, the solution is not ready.

Red flags to watch for

Be cautious of cloud pitches that promise simplicity without addressing manufacturing realities. Watch out for:

- One-size-fits-all designs

- No manufacturing references

- Vague security ownership

- No disaster recovery testing

CEO Perspective: Why Cloud Decisions Are Business Risk Decisions

Most manufacturing cloud discussions focus on technology. CEOs look at something different.

From an executive perspective, cloud decisions are not IT upgrades. They are business risk decisions.

The question isn’t whether the cloud is modern enough. The question is whether the business can continue operating when something goes wrong.

California manufacturing CEOs are increasingly asking three things:

What does downtime actually cost us per hour?

When production stops, the cost isn’t limited to lost output. It includes missed shipments, contractual penalties, customer trust, and internal chaos.

From a CEO’s seat, cloud solutions must be evaluated based on:

- Recovery time, not feature sets

- Operational impact, not technical elegance

If a cloud design cannot clearly answer how fast production systems recover, it’s not executive-ready.

Are we reducing risk or just moving it somewhere else?

Many cloud migrations fail because they simply relocate risk.

Servers move to the cloud, but:

- Backup strategies remain weak

- Security ownership is unclear

- Disaster recovery is never tested

From a CEO’s standpoint, a cloud solution only makes sense if it materially reduces business risk, especially ransomware and extended downtime.

That’s why hybrid cloud models often outperform all-cloud approaches in manufacturing. They reflect operational reality instead of marketing promises.

Who is accountable when something breaks?

Executives don’t care which vendor hosts which workload when production is down at 2 a.m.

They care about accountability.

A CEO-aligned cloud strategy clearly defines:

- Who owns recovery decisions

- Who tests disaster recovery

- Who is responsible for security gaps

- Who communicates during incidents

If accountability is fragmented across vendors, the risk stays with the business.

Will this still work when we grow, acquire, or change?

Manufacturing businesses evolve. New product lines, acquisitions, compliance requirements, and customer audits are inevitable.

CEOs favor cloud strategies that:

- Scale without re-architecting

- Support compliance growth

- Avoid locking the business into fragile designs

Flexibility is not a technical preference. It’s a growth requirement.

Why This Perspective Matters

This executive lens is what separates cloud projects that quietly succeed from ones that stall, overrun budgets, or create new risks.

For manufacturing companies in California, the best cloud solutions are the ones that:

- Keep production running

- Reduce exposure to disruption

- Provide clarity instead of complexity

Technology supports the business. Not the other way around.

A Real-World Manufacturing Cloud Scenario

A mid-market California manufacturer was running production systems on aging servers with limited backups. Recovery times were measured in days.

By moving to a hybrid cloud model, they:

- Reduced recovery time to hours

- Improved ransomware resilience

- Gained predictable infrastructure costs

- Avoided production disruption during upgrades

The technology mattered. But the planning mattered more.

When to Bring in a Manufacturing Cloud Partner

Cloud is not just infrastructure. It touches operations, security, compliance, and finance.

Manufacturers benefit from partners who understand production environments, not just cloud platforms. A vCIO and vCISO approach helps align cloud decisions with business risk, not vendor incentives.

Cloud That Supports Production, Not Disrupts It

For California manufacturers, cloud solutions are about resilience, control, and continuity. Not buzzwords.

A suitable manufacturing cloud solution can help you cut down on downtime, keep your intellectual property safe, and enable growth without creating new risks.

If you are in California and looking for a manufacturing cloud solution, but at the same time, you want a straightforward, risk, focused perspective, Consilien can help you evaluate different options and remain unbiased to vendors.